👷Hard Hat Safety: A Simple Step That Saves Lives

On a construction site, hazards can come from any direction: overhead work, falling tools, shifting materials, unexpected movements. One of the simplest and most effective ways to protect yourself is also one of the most overlooked: wearing your hard hat correctly, every time.

Why Hard Hats Are Essential ❔

An informative video on the importance of hard hat safety and the difference wearing one can make.

Construction sites contain multiple overhead risks from elevated work platforms and scaffolding to cranes, ladders, and material staging areas. A properly worn hard hat protects against:

Impact From Falling or Flying Objects - Tools, materials, debris, and equipment can fall from height without warning. Hard hats are engineered to absorb and distribute the force of impact, reducing the severity of injury.

Head Strikes and Bumps - Confined areas, low structures, and moving equipment create head-height hazards. A hard hat acts as a buffer between workers and sharp or solid surfaces.

Electrical Hazards - Many hard hats are rated to protect against accidental contact with low-voltage electrical circuits. Wearing the correct class of hard hat can prevent burn injuries or electrocution.

Visibility and Identification - Color-coded hard hats help identify roles on site (supervisors, visitors, subcontractors, first aid responders), improving communication and emergency response.

Hard Hat Types and Classes

Selecting the appropriate equipment for the work environment is a key part of compliance with British Standards (BS), such as BS EN 397.

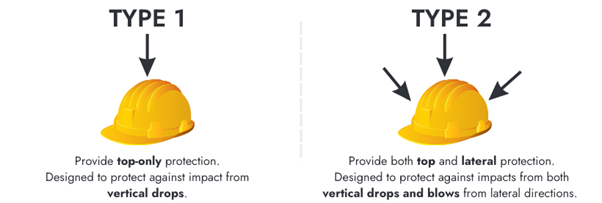

Safety helmets are generally classified into two main types:

Types (Impact Protection)

Type I: Designed for top-of-head impact.

Type II: Protects against both top and side impacts.

Classes (Electrical Protection)

Class G (General): Tested to withstand up to 2,200 volts.

Class E (Electrical): Tested to withstand up to 20,000 volts.

Class C (Conductive): No electrical protection - intended for comfort and ventilation only.

Recent Prosecution: A UK builders’ merchant received a £14,000 fine for providing hard hats that failed to comply with the EN 397 standard.

Proper Use: How to Wear a Hard Hat Correctly

Hard hats only provide protection when worn and adjusted properly. Key guidelines include:

Wear it level, not tilted or backward.

Keep the suspension adjusted so the hat fits snugly and does not shift during movement.

Always secure the chin strap if working at heights or in windy conditions.

Do not drill holes, paint the shell, or apply harsh chemicals. Modifications can weaken the material and reduce protection.

Keep long hair tied up to ensure the hard hat sits correctly and safely.

Inspection and Maintenance ⚙️

Hard hats require regular inspection and care to remain effective.

Daily Checks

Look for cracks, dents, or deformities in the shell.

Inspect the suspension for frayed straps, broken clips, or wear.

Ensure the suspension sits properly in the shell and is not twisted or damaged.

Ongoing Care

Keep hard hats out of direct sunlight when not in use—UV exposure can degrade materials.

Store in a cool, dry place, not in a vehicle or on a dashboard.

Clean with mild soap and water, never with solvents.

Replacement Guidelines

Replace your hard hat immediately if:

It has been struck by a falling object

It shows signs of cracking or brittleness

The suspension system is worn, stretched, or damaged

The manufacturer’s service life guidelines have been reached (often 3–5 years for shells and 1–2 years for suspensions).

Common Misuses to Avoid

To maintain full protection, avoid:

Wearing hard hats backward without manufacturer approval

Using stickers or paint that may weaken the shell

Wearing hoodies, caps, or bulky winter gear underneath that can affect the fit

Leaving hard hats on machinery or dashboards where they can warp

Creating a Culture of Head Protection

Hard hat safety works best when it is part of a broader safety culture. Employers should:

Provide training at start of employment and at regular intervals

Enforce PPE rules consistently across all sites

Replace damaged equipment immediately

Lead by example - supervisors should always wear proper PPE

Encourage workers to speak up about unsafe conditions or damaged gear

Protecting workers’ heads protects their lives. A well-maintained, properly worn hard hat is a simple tool that prevents some of the most severe construction injuries.

Additional information on hard hat safety is available on the HSE website - click here